SPLINTERS

Tennessee Valley Woodworkers

Vol. 18/ Issue 7 July

2003 Editor: Tom Gillard Jr.

Vol. 18/ Issue 7 July

2003 Editor: Tom Gillard Jr.

Meeting Notice:

The next meeting of the TN Valley Woodworkers

Will be held, July 15th, at 7:00 p.m. in the

Duck River Electric Building, Dechard, TN

All interested woodworkers are invited!

The following people have agreed to serve as contacts for their particular

skills. If you have questions, suggestions for activities, or other

comments relating to these skills, please call these folks. Their

interest is to help the club better serve their area of expertise.

Your participation with them will help them achieve that goal.

Design: Alice

Berry

454-3815

Finishing: Phil

Bishop

967-4626

Turning: Tom

Church

967-4460

Carving: Harry

May 962-0215

Sharpening:

Bob

Reese

728-7974

Joinery: Ross

Roepke 455-9140

Health and Safety:

Maurice

Ryan 962-1555

List of

Club Officers

President: Doyle

McConnell

V. President: Ken

Gould

Secretary: Barbara

Keen

Treasurer: Henry

Davis

Publicity: Loyd

Ackerman

Newsletter Editor Tom Gillard

Jr.

GOD BLESS AMERICA!

Please remember, in your thoughts and prayers, all our Troops heading

for the Middle East.

FOR MEMBERS ONLY

Don't forget about the club give-away this year.

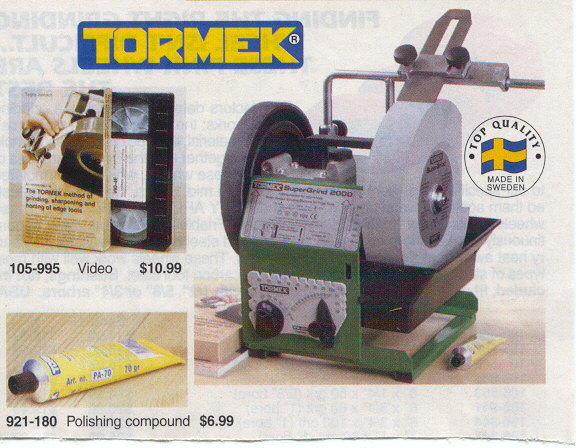

We have a Tormek sharpening machine for some lucky winner at the Christmas

party.

New Business:

The Fall Seminar, “Laws of Woodturning” has been scheduled for October

25, 2003. Subject matter offered will be both basic and intermediate

from the artistic and practical application. Also, included will

be the importance of determining the speed of the lathe. Loyd’s example

of the “exploding bowl” emphasizes the need for correct speed. The

location of the class and more details of the seminar will be forthcoming.

Jim Van Cleave announced

that he would be teaching others the art of making cockbead sometime the

last of July or the first of August. A sign-up sheet was provided

to determine interest and possible dates.

Andy Weaver announced

that there is a festival, “Great Outdoor Week-end on the Mountain”

being planned for October 17,18 & 19 in the Gruetli Park. Members

are invited to participate with demonstrations and sale of craft items.

See him for further details.

There was a good story on NPR the other day. Click here

for the link. Maybe we should try this again. I know we

use to do this many years ago...

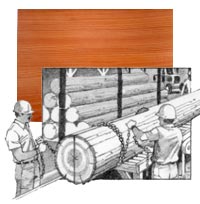

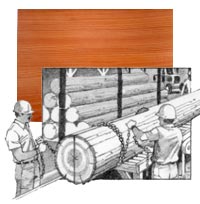

Greenheart

Duck! Here Comes the Greenheart

Explosive as well as poisonous, greenheart does have some good qualities–like

durability that rivals teak’s.

Sawyers in Guyana, Surinam, and Venezuela have nasty enough work in

the tropical

heat day in and day out without worrying about exploding logs on top

of it all. But

when a load of greenheart comes to the mill, they treat the logs like

a truckload of

ticking time bombs.

The species Ocotea rodiei, it seems, has an usual tendency to split

apart so quickly

and with such force that pieces of the log can fly when air hits the

saw kerf. In at least

one instance, sections of a greenheart log actually pierced a mill

roof. To prevent

such mishaps, mill hands secure the section of the log that has already

passed

through the saw with a stout chain.

As if controlling greenheart’s explosive tendency isn’t a scary

enough situation, all who work the wood also must avoid

getting splinters. That’s because greenheart, while nontoxic

and nonirritating to the touch, somehow causes severe

infection when splinters of it penetrate the skin.

"Why do these lumberman even bother with the wood?" For several

reasons. Besides being a pretty wood, greenheart

ranks second only to teak in its natural resistance to marine

borers and other insects attacks.

It also has high shock resistance, great crushing strength, a

high density, and takes a polish with little effort. Such

attributes attract ship and boat builders. Before man-made materials,

fishing rod makers liked greenheart because it

bent without breaking.

Illustration: Jim Stevenson.

Show & Tell:

Loyd Ackerman showed a walnut

vessel turned on center noting that the pith had been removed to prevent

cracking. The excellent finish was 3 coats sanding sealer and 6 coats

of Deft. He also showed a purple heart

bowl with a burnt edge. The edge was made by holding cardboard

against the vessel surface, while the bowl was turning on the lathe.

Hugh Hurst showed a beautiful Mesquite

natural edge bowl. He noted that the Texas wood cuts as if it

were butter. He also is in the process of making a cannonball bed

and showed the practice posts that

he had turned. Often, the practice turnings can eliminate

the errors that may occur in turning.

Bob Leonard brought his version of the “wedgie”

along with the article in a recent publication about the virtues of using

this when planting.

Doug Dunlap brought a plant stand constructed with

the use of splines of plywood. The beautiful stand was constructed

of cherry and walnut with a boiled

linseed oil finish. He expressed appreciation to Henry Davis for the seminar

recently held.

Bill Davis brought a maple

plant stand, finished with 3 coats of Deft.

Bill Duncan showed a plant

stand top. The top was finished with 3 coats of tung oil, applied by

pouring the oil on the surface and rubbing with the heel of his hand.

Ross Roepke gave hints concerning glue-up processes

on multiple part assemblies. He also showed push sticks made for the table

saw to cut small pieces safely.

Bob Reese brought a

violin, which was his 15th. His wife played it beautifully.

This instrument had a visible glue joint on the back, which had been cleverly

disguised with an artist painting. Also, his hand-powered

car for his great grandchild was intriguing to all the “little boys”.

The walnut music stand with adjustable positions was beautiful.

Helpful hold-downs

Keep your fingers safe and your workpiece steady with a few pieces

of wood and the turn of a T-nut.

For drilling jobs, it’s essential that you hold the workpiece securely

to the table and against a

fence before engaging the bit. With smaller workpieces you may not

have clamps with the

necessary jaw depth, and, as shown in the example left, you don’t want

to get your fingers

close to knuckle-busting circle cutters. Hold-downs are the answer,

and here’s a version that

will only set you back the cost of the knobs and all-thread rod. (Many

woodworking catalogs

carry such knobs.) Use the full-size pattern and drawing, below, to

make a hold-down.

We drilled three holes into each side of our drill-press table

for accommodating workpieces of various sizes. Each hole

is outfitted with a T-nut for accepting the 1/4" all-thread rod.

(WOOD-Online)

June Program

Ken Gould introduced our guest, Howard

Rust, Jr, of Northside Clocks who presented an interesting and informative

program regarding the history of clock making, noting that the art originated

in China in 1365 and was first practiced in this country in 1750.

The first clock maker, Eli Terry paid the fees for Seth Thomas and another

gentleman to come to this country. They were indentured to him for

a period of 10 years. Only 3 clocks were made each year. The internal

works were wood with the use of quarter-sawn oak as front and back

plates and apple for all the gears. The apple wood is extremely hard,

holding up well through much use. The internal works of a clock of

this period evidenced this. Each member had the opportunity to examine

this.

FREE Woodworking Charts

If you're like most woodworkers,

you have at one time or another

ruined an expensive drill bit or

cutter by running it at too high a

speed in your drill press. So how

do you go about finding out the

recommended operating speed

for any given tool so this doesn't

happen? Up until now, it's been almost impossible!

DOWNLOAD CHART HERE

September 22 thru 27 --

Coffee County Fair. TVWW has a building in the Morton Village section

of the fairgrounds. Morton Village is behind the livestock barn and

the main arena area. We will be exhibiting and demonstrating there

during the week but will have a concentrated effort on Friday and Saturday

(26,27th).

FOR SALE

Wood for Sale:

Contact Ross Roepke regarding

2000 board feet of cherry and 1000 board feet of walnut.

Sears: 6 x 48" belt / 9" dia disk sander

Comes with a few extra disks It has the stand to go with it.

Click

here to view some pictures of the sander

Contact: Tom Gillard Jr.

455-6651(H), 393-0525(W)

$125.00

*** Beginning with the July 22 2003 meeting the Stones River Woodworkers

Club will meet at the Farm Bureau Insurance Building, 818 S. Church

Street (Highway 231) Murfreesboro,TN at 7:00 PM.

10 % OFF Fine Woodworking

Books from Taunton Press

…We’re open Monday thru Saturday

SEE YOU ON THE

15th!

Vol. 18/ Issue 7 July

2003 Editor: Tom Gillard Jr.

Vol. 18/ Issue 7 July

2003 Editor: Tom Gillard Jr.