SPLINTERS

Tennessee Valley Woodworkers

Vol. 18/ Issue 2 February

2003 Editor: Tom Gillard Jr.

Vol. 18/ Issue 2 February

2003 Editor: Tom Gillard Jr.

Meeting Notice:

The next meeting of the TN Valley Woodworkers

Will be held, February 18th, at 7:00 p.m. in the

Duck River Electric Building, Decherd, TN

All interested woodworkers are invited!

The following people have agreed to serve as contacts for their particular

skills. If you have questions, suggestions for activities, or other

comments relating to these skills, please call these folks. Their

interest is to help the club better serve their area of expertise.

Your participation with them will help them achieve that goal.

Design: Alice

Berry 454-3815

Finishing: Phil

Bishop

967-4626

Turning: Tom

Church 967-4460

Carving: Harry

May 962-0215

Sharpening:

Bob

Reese 728-7974

Joinery: Ross

Roepke 455-9140

Health and Safety:

Maurice

Ryan 962-1555

List of

Club Officers

President: Doyle

McConnell

V. President: Ken

Gould

Secretary: Barbara

Keen

Treasurer: Henry

Davis

Publicity:

Loyd Ackerman

Newsletter Editor Tom Gillard

Jr.

GOD BLESS AMERICA!

Please remember, in your thoughts and prayers, all those touched by

the Space Shuttle Tragedy

I hope everyone survived that COLD weather we had a few weeks ago.

Have you ever noticed that during the coldest, darkest days of winter the

mailman can bring you something to take your mind off of the weather.

No, not your tax forms, but the new seed catalogs. I got mine a few

weeks ago and it was a real pleasure to look through it and dream of warmer

times and the taste of fresh vegetables again. Especially the corn!

What it Takes to be Shaker

The first Shakers came to America from England

in 1774. Following them from the outside world,

they recruited members to live and work in

self-sufficient, communal settlements. By the early

1800s there were 18 Shaker communities in seven

states.

Shakers became known in the world outside their settlements for

excellence in whatever they grew or made, especially their furniture. In

keeping with the Shakers' unadorned lifestyle, they built purely functional

pieces devoid of ornamentation. Yet their furniture displayed delicately

constructed, graceful lines, and sensitivity to proportion reminiscent

of

Danish modern or Scandinavian-style furniture of the 20th century.

The 1830s marked Shaker furniture's Golden Age. But they continued

producing it, even commercially, into the early 20th century.

Native wood from the forest

Shakers used local trees. Ash,

basswood, birch, butternut, cherry,

white pine, and sugar maple

(especially figured) were common in

New England settlements. Beech,

chestnut, yellow poplar, and walnut

were added in Kentucky and Ohio.

Fruitwood (apple, pear, etc.) was

used widely for pulls.

Finishes varied with the stock

Because several woods went into

chest of drawers, cabinets, and

tables, these types of furniture were

paint was opaque. Later, it was a

wash through which the grain was

visible with varnish as a top coat.

Chairs and rockers made of only one

kind of wood were varnished or

shellacked after staining. Darker

hardwoods, such as cherry, were

finished with linseed oil.

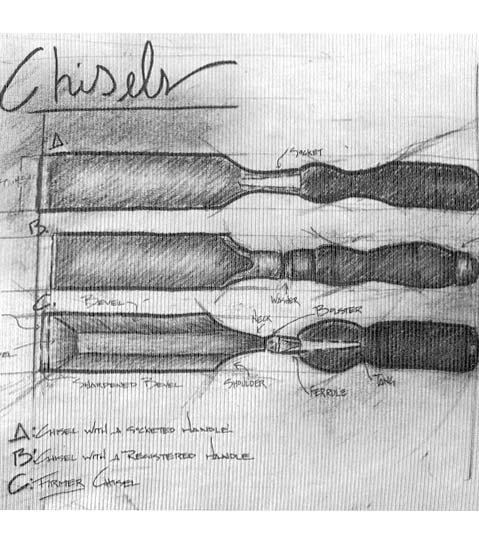

Joinery that stayed together

tongue-and-groove cutting machine,

so they employed it to edge-join

boards. Splined grooves, butt joints,

lap joints, through tenons (wedged

and keyed), and dadoes for shelving

were favorite joinery methods.

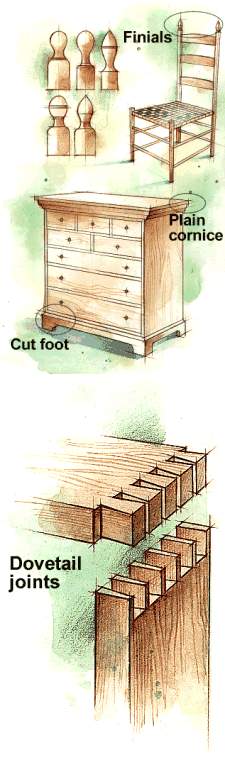

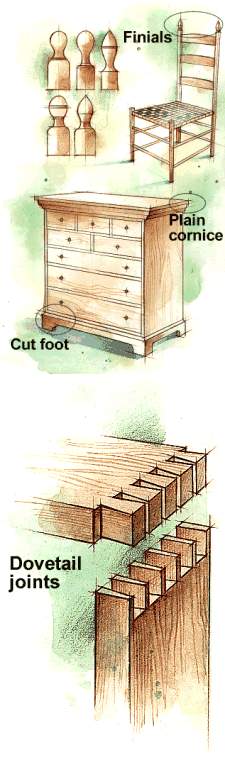

Dovetails are the most observable

construction feature. They were used

for their strength and durability rather

than for appearance.

Details didn't decorate

Shaker case goods featured drawers,

usually combined with larger storage

spaces covered by frame-and-panel

doors. Except for a restrained

top-edge molding in cove,

quarter-round, or bullnose shape,

case goods were simple. They sat

directly on the floor, had cut feet, or

applied legs.

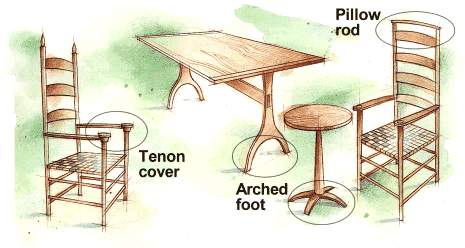

Side chairs, hung on wall pegs when not in use, were light and graceful

with plain turned stiles, legs, and stretchers. Finials at the top of the

stiles

were intended as handles to lift the chair, not as decoration. The bottom

of

the back legs usually had turned tilters (early Shaker) that protected

the

floors. Later, tilters were commonly made of brass.

Rocking chairs had finials atop their stiles, too, or a plain crossbar

on

which to hang a pillow. On the top of the front arms were

mushroom-shaped, wooden tenon covers. Chair and rocker seats featured

woven wood splints, rush, leather, cane, and, after 1830, colorful cloth

tape made on special looms.

Trestle tables were known for gracefully arched feet (on small tables,

too).

A raised stretcher beneath the top added leg room for seating comfort.

Could you please move over a little so I

can see what that is on the wall behind you...

I've never seen one of those before...

*******************************************

We had THREE new members last month: David Jacobs, Pat Patrick, and

Howard and Janice Bauder.

WELCOME to the TN Valley Woodworkers

*******

Henry Davis said it was time for this years dues

to be paid *******

FOR SALE

Please see the CLASSIFIED adds on the web site for these items...

Wood dust can cause cancer:

study

Improper protection could lead to cancer in the nasal

cavity or sinuses, OSHA says

"As a general rule hardwoods are more hazardous to human health than

softwoods," OSHA states. " There are exceptions - in particulate

Western red cedar, a softwood, is usually identified as one of the most

hazardous to human health.

READ THIS!!!

WOOD DUST*

First Listed in the Tenth Report on Carcinogens

CARCINOGENICITY

Wood dust is known to be a human carcinogen, based

on sufficient evidence of carcinogenicity from studies in humans. An association

between wood dust exposure and cancer of the nose has been observed in

many case reports, cohort studies, and case-control studies that specifically

addressed nasal cancer. Strong and consistent associations with cancer

of the nasal cavities and paranasal sinuses were observed both in studies

of people whose occupations are associated with wood dust exposure and

in studies that directly estimated wood dust exposure.....

***READ THIS REPORT!!!***

10th Report on Carcinogens

U.S. Department of Health and Human Services

Public Health Service

National Toxicology Program (<== click on this link to see

the report)

(scroll down to wooddust)

SHOW AND TELL:

(some pictures in the gallery)

Tom Gillard brought in a piece of red oak that he had put wood putty

on one side, applying cross grain and than sanding off. He used Elmers

white wood putty. He than put a finish on it and it does a real good job

smoothing grain.

Dave Whyte made a tendon jig that can be used with a table saw. It slides

in the rail slot. It was made out of Cherry and Walnut and had adjustments

to hold wood (even long pieces). It also has an adjustment for the depth

and can also do miters. He also showed a Jewelry box made out of Sassafras

with walnut inlay. It also had inlay around the feet.

Winfield Bennett showed us a frame made out of paint paddles. It was

a very unique frame and it was done with just a pocketknife. He said that

type of art is called Tramp

Art. Tramp

Art, Tramp Art, too.

Karen Kerce brought in several bowls with starting with square bottom.

One was made from very old wood. It was checked and made an interesting

bowl. One was out of Mahogany and was out of Box Elder. She also did a

larger one from Black Walnut.

Tom Cowan talked about the emotional side of woodworking, saying that

if something has a story behind it than it is more interesting to the craftsman.

He found a book in Chicago on the history of a family of cabinetmakers

named Dunlap from Scotland. Because of reading this book it made him interested

in making a corner cabinet that incorporated some of the things he learned

from the book and he also carved on it with a chisel. If not for the book

and the emotional side he may not have made the cabinet. He brought the

book in and a picture of the cabinet.

Henry Davis saw a vacuum attachment for a drill press in splitters 3

issues back. He made it and brought to show and tell. He also made a plant

stand that has many angles and different types of joints in it. He said

this type stand might make a good future workshop. He also brought in a

piece of wood he had bought at Phil Bishop’s auction a long time ago. It

was twisted and he had to do a lot of work to smooth it but turned out

very good and will use for some future table.

Ross Roepke brought in a piece of paper and a board with 2 nails in

it and showed us how to make an ellipse. This was done since someone on

our Webb site had asked how to do this simply. He also brought in an apple

box he made for an auction at Trinity Care Center. He also made a Walnut

table for using at church for the guest book. It fits under the last table

he did for storage.

Ken Gould made a jig for ellipses that you use with a rotor. He had

a block of wood that he made 2 dovetail slots at 90 degrees to each other

and than put 2 pins in. He set up cross piece for rotor and than put multiple

holes in it for circles or to use cross pin jig. You just decide on the

size you want and set pins on that size and you can make the ellipse.

Bob Leonard made a fire truck. It was a model of 1928 Aronfox and it

has 28 different species of wood in it. It has about 200 pieces that he

had to make. It took him about 180 hours to build it. He finished with

Deft Spray. The pattern was from an issue of Fine woodworking 1989.

Bob Reese brought in 2 books that contain everything he knows about

violin making. He made them for his Children and Grandchildren in case

they ever want to make violins. Since he bought a new computer he has redone

them and has about 500 pictures and a total of 1000 pages the rest being

text. He put it on 3 CDs. He thinks it probably is about the equivalent

of a 5-year apprenticeship program on violin making. It was 15 years in

the making.

Steve Shores he made a walnut mirror with very nice figuring. He also

brought in another mirror made of maple and painted on the back by his

neighbor. They were finished with Lacquer.

Loyd Ackerman brought in a table he built in 1992 out of popular which

he uses for a telephone stand. He used Aniline dyes on it. He showed another

table that he made that has laminated bend front. Which was Walnut over

plywood with walnut on back also. He tapered the legs first and than turned

them just enough to get rid of flats. He found this to be an easy way to

do them.

Houston Clark made a music holder. The post he made out of 2 X 4’s which

he cut in half so he could turn the bark on edge to the inside and it would

not show. He used yellow pine from some old shelving for the braces. He

sprayed it with several coats of polyurethane high gloss and than one coat

of semigloss to take off some off the shine.

Henry May carved a Santa out of basswood, which was painted. He also

showed a spirit out of Cherry and one out of Pecan. He also showed a Squirrel

monkey on a tree that he carved from 1 piece of wood.

************************************************************************

THIS MONTH

Useless tools, Bring something you thought you couldn't live

without, until you got it home and it hasn't been out of the box yet.

WEB

SITES of INTEREST

Members sites:

Doyle

McConnell's page

Loyd

Ackerman's Page

Falls Mill

Russell Brown's Web Page

Geoff Roehm

Resourse Sites:

American Association of Woodturners

WOOD

ONLINE newsletter

Scott

Phillips Video Help sessions

Arrowmont

School of Arts and Craft

Appalachain

Center for the Arts

Forest

Products Lab. 1999 Wood Handbook

Woodworker's

Journal

WOOD

Online TVWW page

Kevin's Woodturnings

The Oldham Company

The Woodworker's Choice

10 % OFF Fine Woodworking

Books from Taunton Press

…We’re open Monday thru Saturday

SEE YOU ON THE

18th!

Tom Gillard Jr.

Vol. 18/ Issue 2 February

2003 Editor: Tom Gillard Jr.

Vol. 18/ Issue 2 February

2003 Editor: Tom Gillard Jr.