SPLINTERS

Tennessee Valley Woodworkers

Vol. 17/ Issue 4

April 2002

Editor: Tom Gillard Jr.

Vol. 17/ Issue 4

April 2002

Editor: Tom Gillard Jr.

Meeting Notice:

The next meeting of the TN Valley Woodworkers

Will be held, April 16th at 7:00 p.m. in the

Duck River Electric Building, Dechard, TN

All interested woodworkers are invited!

The following people have agreed to serve as contacts for their particular

skills. If you have questions, suggestions

for activities, or other comments relating to these skills, please

call these folks. Their interest is to help the

club better serve their area of expertise. Your participation

with them will help them achieve that goal.

Alice

Berry 454-3815 Design

Phil Bishop

967-4626 Finishing

Tom

Church 967-4460 Turning

Harry May

962-0215 Carving

Bob

Reese 728-7974 Sharpening

Ross Roepke

455-9140 Joinery

Maurice Ryan 962-1555

Health and Safety

List of

Club Officer

President: Bob Leonard

V. President: Doyle McConnell

Secretary: Barbara Keen

Treasurer: Henry Davis

Publicity: Maurice & Ruth Ryan

Newsletter Editor: Tom Gillard Jr.

GOD BLESS AMERICA!

CALENDAR of EVENTS

Spring seminar: April 20th @ Foothills

Craft, Manchester

Picnic: June 22nd @ Falls

Mill

Coffee County Fair : 3rd week in September

Fall seminar :October time frame

Christmas party: December 6

** It was also suggested that we should have another “turning B” and

possibly another carving workshop.

The seminar theme will be finishing and refinishing, and it will be

held at the classroom at Foothills Craft building in Manchester.

The time will be from 9:00 AM with a break for lunch at one of the local

restaurants. It will end somewhere around 3 PM.

The presenter will be David Duggin from Woodbury. David is an antique

dealer who does his own finishing.

The cost will be $20.

Come and let's have a good time.

SHOW AND TELL:

*Don Powers brought in a turned vase.

*Phil Bishop showed us 1 of the supports he is making for a Granite

Counter top. He carved, bandsawed and used the router on it.

They are made out of Alder.

*Tom Gillard Jr. showed us a sailboat tiller made out of salvaged teak.

*Jim Van Cleave told us about a museum in Winston Winston-North Carolina

that had 30 rooms of period furniture. He brought in a large bowl

and a bird feeder he made and another one that someone else made that was

an example of how not to make a working bird feeder.

*Jim Parker brought in cherry legs that he made. He said he drew

the legs out on 2 sides of a squared block of wood and than band sawed

them. He than put in lathe and cut foot and than finished shaping

with a rasp and spoke shave.

*Loyd Ackerman brought turned walnut bowls.

*Doyle Mc Connell brought in a goblet he made and finished with beeswax.

He also brought in a picture frame that he made with an upturned angle.

He had problems because of the upturn angle holding for gluing and finally

used hot glue to put on temporary blocks that he could clamp. He

used lacquer finish.

Steve Shores made a jig for holding tools while sharpening.

*Billy Mays showed us a carved elephant out of Tupelo and he finished

with Johnson floor wax. He also made a Dolphin out of basswood with

a black walnut base.

*Ken Clark brought in a bandsaw box that he got out of Wood issue 51.

He used cherry stain on it and floor wax.

*Chuck Tayor brought in a bowl he started at the turning “ b” which

was cherry with a lacquer finish and he also showed a natural edge bowl

made out of Red Bud.

*Herald Hewgley brought in a chair, which was a copy of an antique.

It was made out of Cherry and finished with Valspar Satin Black finish.

He sprayed 4 light coats.

*Ken Gould made a lathe bench for his new lathe. He also did

the black smith work on the Iron straps. It was cherry with 2 coats

of cherry stain and 2 coats of Deft oil.

*Jim Kemp showed us a Myrtlewood pencil holder he had made.

April Meeting

Loyd will be presenting the program next month on "Wood

movement as it Effects Joinery". (<---click

there)This will fit in with our joinery theme this year very well.

Loyd has done a lot of work in this area and as always I am sure that it

will be well presented.

-Doyle

--------------------------------------------------------------

"I just wanted to say that this was my first time to be a part of a seminar

of this sort, since I started with American Saw. I truly enjoyed

the time I could spend with you all. I'm sure I speak for Ray Hughes,

Glenn Tetro, and Doug Walston with Precision Blade when I say that, organizations

like yours are an asset to any community."

Thank you for your time.

Sincerely,

Mark Gomez

NAME TAGS

The subject of name tags came up at the last meeting. Our name tags

were made by K&S TROPHIES , 510 Country Club Drive , Tullahoma.

They were about $5.00 including tax the last time we checked. When in Tullahoma

you can go by and have one made. The tags are 1" x 3" with white letters

on a blue background. Just tell the folks that you want a Tennessee Valley

Woodworkers name tag. If you are never in Tullahoma, Henry Davis will be

happy to take care of it for you, see him at the February meeting or give

him a call at 393 - 3191.

Mini Lathe Give Away.

To show our appreciation to our loyal and faithful members your Executive

Committee has again this year decided to give a prize to one lucky member.

To be eligible to win the lathe just sign the drawing register at each

regular club meeting that you attend between now and December. That means

that if you attended the January meeting and attend every meeting from

now through November your name will be in the drawing 11 times.

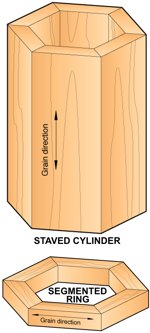

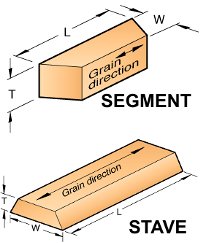

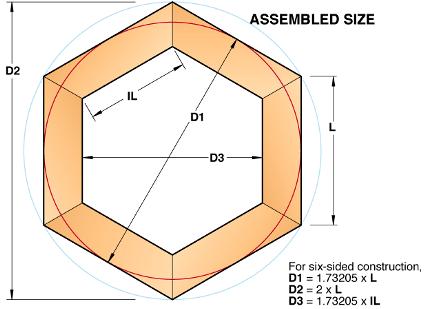

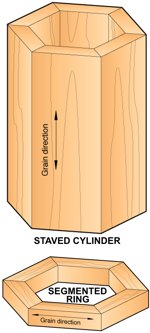

Staves and Segments

Staved or segmented construction figures in a lot of projects, from ornamental

bowl turnings to porch pillars. A question we often hear is: What miter

angle (or bevel) do I need? Another recurring question is: How long (or

wide) should I make the pieces? Finding those answers is relatively easy.

Here’s how to do the math.

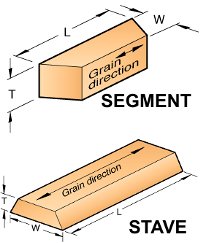

First, let's get our terminology straight.

Staved cylinders and segmented rings may seem alike, but they're two different

breeds of cats. As shown in the Staved Cylinder and Segmented Ring illustrations,

the individual pieces in a segmented ring are miter-cut (shown in the Segment

illustration) and joined at the ends. In a staved cylinder, the component

parts are bevel-cut (shown in the Stave illustration) and joined edge-to-edge.

So, things can become confusing when we start talking about the distance

between the angles. On a stave that distance is the width, but on a segment,

it's the length. For this article, we'll refer always to length. Substitute

width" if you're cutting staves.

Also for simplicity, we'll call the angled cuts miters, even

though we know they may be either miters or bevels. Note, too, that this

article only covers straight-sided cylinders or flat rings. Tapered cylinders

or rings with sloped sides call for compound cuts.

Corner and miter angles for various numbers of

sides

|

no. of sides

|

corner

|

miter

|

|

6

|

60°

|

30°

|

|

8

|

45°

|

22-1/2°

|

|

10

|

36°

|

18°

|

|

12

|

30°

|

15°

|

|

16

|

22-1/2°

|

11-1/4°

|

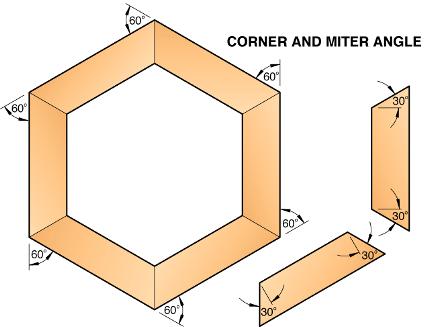

What's your angle?

A full circle contains 360°. So, to make a closed construction

out of straight pieces, the corner angles must add up to 360°. In the

simple figure with six equal-length sides shown in the Corner and Miter

Angle illustration below, the six 60° corners add up to 360°. But,

as shown, 60° is not the angle you need to cut on the ends of each

piece. Because two sides come together to make the angle, each side must

be miter-cut to exactly half the total corner angle, or 30°.

Here's the rule for finding the angle:

To determine the corner angle for a figure with any number of equal-length

sides, divide 360° by the number of sides. To find the miter angle,

divide the corner angle by two.

How big will it be?

To figure out the measurement across the assembled construction, shown

as D1 in the Assembled Size illustration, multiply the side length (L)

times the inside-diameter factor for the appropriate number of sides from

the chart below. This dimension, which is the diameter of the largest circle

that can be drawn inside the outline of the glue-up, also represents the

diameter of the largest round piece that could be sawn or turned from the

assembled ring. You can calculate the width across the points, shown

as D2, by multiplying the side length times the outside-diameter factor.

FACTOR TO FIND DIAMETER

Diameter

|

no. ofsides

|

inside (D1)

|

outside (D2)

|

|

6

|

1.73205

|

2

|

|

8

|

2.41421

|

2.61313

|

|

10

|

3.07768

|

3.23607

|

|

12

|

3.73205

|

3.86370

|

|

16

|

5.02734

|

5.12583

|

And if you need to know the diameter of the opening in a ring, shown

as D3, just multiply the length of the short edge of the segment (IL) by

the appropriate inside-diameter factor. You can work backwards, too,

to find the stave length required to produce a given diameter. In this

case, divide the desired diameter by the factor from the chart. To find,

for instance, the side length for a hexagon that measures 24" across (D1),

divide 24" by the inside-diameter factor (1.73205). Doing this gives us

13.85641", or 13-55/64".

MONTHLY DRAWING: We had our monthly drawing and the following people won

Ray Cole honing blocks, Tom Mc Gill hearing protection, Tom Gillard maglite

, Jim Roy long drill bits, and Gary Hoyle a maglite.

The Fair Maidenhair-tree

Ginkgo biloba is known as a "living fossil tree". This tree's

genetic line spans the Mesozoic era back to the Triassic period.

Closely related species are thought to have existed for over 200 million

years.

Also known as maidenhair-tree, the leaf shape and other vegetative organs

are identical to fossils found in the United States, Europe and Greenland.

Today's contemporary ginkgo is cultivated and does not exist anywhere

in the wild state. Scientists think that native ginkgo was destroyed

by glaciers that ultimately covered the whole Northern Hemisphere.

Ancient Chinese records are surprisingly complete and describe the tree

as ya-chio-tu, meaning a tree with leaves like a duck's foot. Asian

people systematically planted the tree and many living ginkgoes are known

to be more than 5 centuries old. Buddhists not only kept written

records but revered the tree and preserved it in temple gardens.

Western collectors eventually imported ginkgoes to Europe where it was

very popular in large cities like London and Paris.

G. biloba was first brought into the United States by William Hamilton

for his garden in Philadelphia in 1784. It was a favorite tree of

Architect Frank Lloyd Wright and made its way into city landscapes across

North America. The tree had an ability to survive pests, drought,

storms, ice, city soils, and was widely planted. But it did have

a problem...

Stink-bomb Tree

The ginkgo is dioecious. That simply means that there are separate

male and female plants. Only the female plant, when fertilized, produces

the oval, slimy, tan-orange ginkgo fruit. The fruit stinks!

The smell's description ranges from "rancid butter" to "vomit".

This foul smell has limited ginkgo's popularity while also causing city

governments to actually remove the tree and ban the female from being planted.

Male ginkgoes do not produce a fruit and are selected as the main cultivars

used to transplant in urban communities.

The slippery pulp can also be a liability. Because of potential

city sidewalks slimed with the pulp of the fruit, urban landscapers recommend

only the male tree. Some of the best varieties found to plant are

'Autumn Gold', 'Princeton Sentry' and 'Fairmont'.

Thanks for the Memories

The extract of ginkgo biloba is bottled as a remedy for several ailments.

Maidenhair-tree's leaf extract is a billion dollar business. According

to one recent report, "In Germany alone, ginkgo biloba prescriptions (it

is prescribed by doctors in Germany) retailed at $280 million in U.S. dollars".

A German manufacturer, Schwabe, sold almost $2 billion U.S. dollars worth

of Ginkgo biloba extract worldwide in 1993.

Gingko biloba is most effective as a concentrated extract, found in

either liquid or tablet form. It has beneficial effects on the circulatory

system, particularly among the elderly. Studies have shown it can help

in treatment of their short-term memory loss, headache, tinnitus (ringing

in the ears) and depression by improving blood flow in the arteries and

capillaries (ask you doctor before trying any new remedies)

Fascinating Facts

* There are no native ginkgoes living in the wild.

All wild trees were wiped out over a million years ago but human intervention

has saved the modern tree.

* Several ginkgoes were the only living survivors

of an atomic bomb blast dropped on Hiroshima by the United States.

* About 50 pounds of dried ginkgo leaves yield a

pound of the medicinal product.

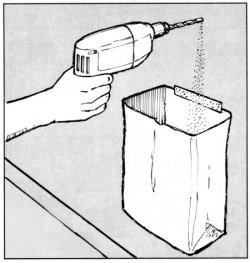

Sacking a mess before it becomes one

Drilling holes in wall paneling,

especially drywall, leaves

unsightly particles on the wall

and the floor, fine dusty material

that's tough to clean up.

TIP: Tape an open paper bag to

the wall a few inches below

where you plan to drill. Once that

bit starts chewing and spitting out

nasty particles, they will fall right

into the sack. When finished

drilling, simply pull loose the

masking tape, and toss away a mess that never happened.

—Earl Hagen, Livonia, Mich.

WEB

SITES of INTEREST

Precision Blade and Tool

Scott

Phillips Video Help sessions

Arrowmont

School of Arts and Craft

WOOD

ONLINE newsletter

Falls Mill

Appalachain

Center for the Arts

Forest

Products Lab. 1999 Wood Handbook

Woodworker's

Journal

TN Association Woodturners

WOOD

Online TVWW page

Kevin's Woodturnings

The Oldham Company

The Woodworker's Choice

Russell Brown's Web Page

Saw Blade Sharpening Services: Branching Out is now offering their

services as a drop off spot to have your saw blades sharpened. The

blades will be picked up (Tuesdays), sharpened, and dropped back off at

Branching Out. The Leitz Tooling Systems out of Collierville, TN

will do the sharpening. Call (393-0525) or stop by for details.

10 % OFF Fine Woodworking

Books from Taunton Press

…We’re open Monday thru Saturday

Webmaster:

Tom Gillard Jr.

Vol. 17/ Issue 4

April 2002

Editor: Tom Gillard Jr.

Vol. 17/ Issue 4

April 2002

Editor: Tom Gillard Jr.

![]()

![]()

![]()