SPLINTERS

Tennessee Valley Woodworkers

Vol. 17/ Issue2

February 2002

Editor: Tom Gillard Jr.

Vol. 17/ Issue2

February 2002

Editor: Tom Gillard Jr.

Meeting Notice:

The next meeting of the TN Valley Woodworkers

Will be held, February 19th at 7:00 p.m. in the

Duck River Electric Building, Dechard, TN

All interested woodworkers are invited!

The following people have agreed to serve as contacts for their particular

skills. If you have questions, suggestions

for activities, or other comments relating to these skills, please

call these folks. Their interest is to help the

club better serve their area of expertise. Your participation

with them will help them achieve that goal.

Alice Berry

454-3815 Design

Phil Bishop

967-4626 Finishing

Tom Church 967-4460

Turning

Harry May

962-0215 Carving

Bob Reese

728-7974 Sharpening

Ross Roepke

455-9140 Jointery

Maurice Ryan 962-1555

Health and Safety

List of

Club Officer

President: Bob Leonard

V. President: Doyle McConnell

Secretary: Barbara Keen

Treasurer: Henry Davis

Publicity: Maurice & Ruth Ryan

Newsletter Editor: Tom Gillard Jr.

GOD BLESS AMERICA!

With the flying of flags comes the problem of what to do with the flags

that become tattered and torn due to use. The proper way of disposing

of these emblems of our Country is to retire them with dignity. This

usually involves burning them. The Boy

Scouts can offer their services if you have a flag that need to be

retired. There are three members of our club that are also members

of the BSA. Danny Bean, Steven Savelle, and Tom Gillard. Please

bring your flag to one of us if needed. Thanks

WELCOME TO OUR NEW MEMBERS

We would like to welcome

Don Miller from Manchester, Don Powers from Winchester and Larry Shockley

from Belvidere who joined us in January. We are happy to have you

with us.

THEME FOR THE YEAR: The survey that

was taken last year asking for member’s inputs on types of seminars they

would like was discussed. Joinery was the number 1 interest with

finishing a close 2nd. A motion was made by Doyle and seconded by Tom Cowan

that Joinery would be the theme for 2002.

SHOW & TELL

John Mayberry brought in 2 turned bowls made out of cherry. John also

brought in a piece of Walnut that had been sawed in half by a sawmill and

it had a walnut imbedded in it, the walnut was cut perfectly in half in

each piece. He finished it and put hinges on it so it closed with

the 2 halves of walnut facing each other. Ross Roepke brought in a stool

made out of Mahogany in the shape of a fiddle. Henry Davis

brought in knee from an English Pub table and the piece he was making to

match it and replace the missing knee. Loyd Ackerman brought in a

segmented bowl and cover. He stated that when you figured out the

proper angles they had to be precise when you cut them. The bowl

was made out of Walnut, Cherry and Slippery Elm. This was his first

attempt at making a segmented bowl and it took him 2 days to complete it.

CALENDAR of EVENTS

Spring seminar: April 20th

Picnic: June 22nd @ Falls Mill

Coffee County Fair : 3rd week in September

Fall seminar :October time frame

Christmas party: December 6

** It was also suggested that we should have another “turning B” and

possibly another carving workshop.

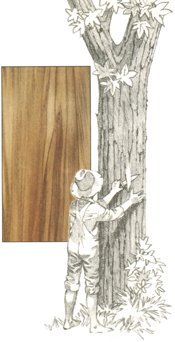

Sweet Gum

In the old days, youngsters

throughout the rural South went to the woods, not the grocery store, for

their chewing gum. There, they sought out a tree with unusual star-shaped

leaves and bark resembling alligator skin. From it they pried off, then

popped into their mouths, yellowish brown balls of a fragrant, resinous

substance with a licorice-like taste. Their treat was the sap of the native

sweet gum tree (Liquidambar styraciflua). Little did they know that this

natural confection, called liquidambar, had been in demand for centuries.

In the old days, youngsters

throughout the rural South went to the woods, not the grocery store, for

their chewing gum. There, they sought out a tree with unusual star-shaped

leaves and bark resembling alligator skin. From it they pried off, then

popped into their mouths, yellowish brown balls of a fragrant, resinous

substance with a licorice-like taste. Their treat was the sap of the native

sweet gum tree (Liquidambar styraciflua). Little did they know that this

natural confection, called liquidambar, had been in demand for centuries.

As reported by historians traveling with the explorer Cortes

in 16th-century Mexico, the Aztec emperor Montezuma relaxed by puffing

a cane stuffed with a mixture of tobacco and a flavoring of liquidambar

from a tropical variety of sweet gum. But even before that, in Europe,

liquidambar was obtained through Asian traders for use in perfume, incense,

and for treating diphtheria and flatulence.

Despite the world demand for liquidambar through the centuries, little

was done with the yield of the North American sweet gum tree. It did serve

as a curative for Confederate soldiers' dysentery, and was harvested during

the Second World War when Asian supplies were cut off.

Sweet gum wood, though, has been another story. The often beautifully

figured stock can resemble walnut. And when quartersawn, it passes as the

costly Circassian walnut fancied for fine furniture and gunstocks.

Box-Joint Jig

A no-frills, always accurate

Basic box-joint jigs like this one have been around for a long time.

What's different here is that we tell you the secrets for setting the jig

up for perfect results! Note: To use this jig you will need a tablesaw,

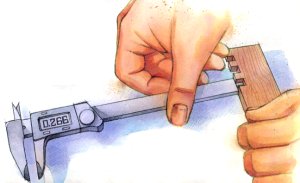

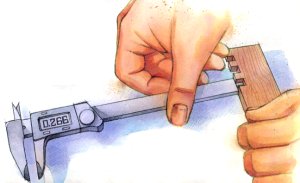

stackable dado set, and a caliper with dial or digital readout. You can

purchase the dial type for $25-$50; digital models cost $60-$75.

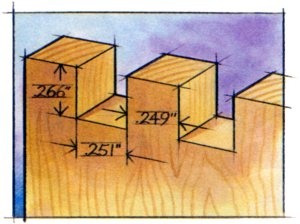

We've found a dial calipers essential because box joints must be cut

with exacting accuracy. Why? Any minor error in the width or spacing of

the individual "fingers," even .001", multiplies itself with every finger

you cut.

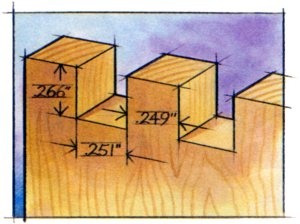

For reasons of design and proportion, you typically make the individual

"fingers" in box joints as wide as the thickness of the workpieces. In

this article, we'll make a jig for cutting 1/4" wide fingers in 1/4"-thick

stock (see the drawing below for the precise dimensions of the joints).

For thicker or thinner stock you adjust the size of the jig's pin and the

width and height of the dado cut accordingly.

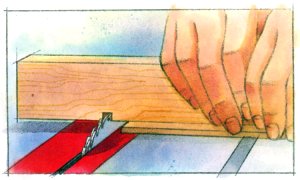

Step 1. Cut parts A, B, and C to the sizes shown in the Exploded View

drawing. Any flat and straight stock will do.

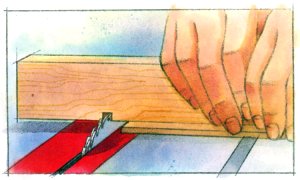

Step 2. Adjust your dado set for a cut that's .001" wider than

the joint fingers (.251" in our example). With stackable dado sets you

can place commercially made shims between the cutters, or make your own

shims from various papers (standard tablet paper measures .002-.005" thick,

some tissue and waxed papers measure .001" thick). Check your adjustment

by measure a test cut with your calipers as shown. Raise the dado set 1/2"

above the tabletop.

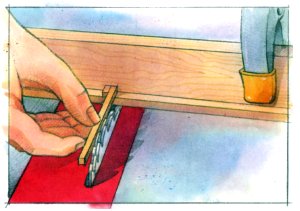

Step 3. Cut the notch that holds the pin in part A. Do this by holding

part A against the miter gauge with part B beneath it as shown. Do not

cut into part B.

Step 4. Cut a 1/4 x 1/4 x 6" strip of hardwood that fits snugly into

the notch you just cut in part A. (The strip should slip into place, yet

fit tightly enough so it doesn't fall out.) Cut a 1-1/2" pin from the strip

and glue it into the notch, flush with the back of part A. Save the leftover

strip. Screw part B to part A.

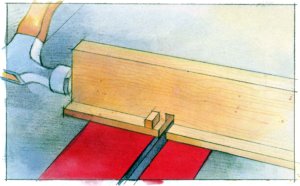

Step 5. Set your miter gauge for a 90° cut. Use the leftover strip

to position the jig assembly on the miter gauge. Do this by aligning the

jig pin 1/4" from the path of the dado set as shown. With the pin aligned,

temporarily clamp the jig to the miter gauge, then affix the gauge to the

jig with screws. Replace the miter gauge into its slot and cut through

parts A and B. Attach the blade guard (C) centered behind the notch you

just cut.

During this and the following steps, apply pressure to the miter gauge

to hold its bar firmly against the right side of the slot. This will keep

its distance from the dado set consistent during cuts.

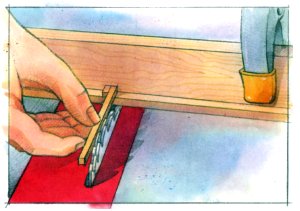

Step 6. Position a piece of scrap stock as shown, and cut

a notch into the scrap piece. Position this notch over the pin and make

another cut. Position that notch over the pin and repeat the cut.

With your calipers, check the width of the fingers. They should be

.001" under your desired finger width. (For our 1/4" fingers the calipers

should read .249".)

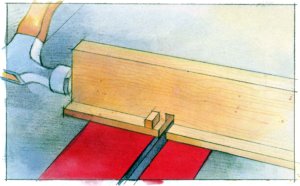

Step 7. Chances are your jig will need some adjustment to achieve

the necessary finger width. If the fingers are too wide, say .255" in our

example, tap the end of the jig closest to the blade with a hammer as shown.

Make more test cuts and tapping adjustments as necessary. If the fingers

are too narrow (.245" in our example), tap the other end of the jig. Even

though the jig is screwed in place, the hammer taps will make these fine

adjustments.

Step 8.

With your calipers, check the depth of the fingers in your scrap stock.

Adjust the height of your blade until the depth reads .016" more than the

width of your fingers (.266" in our example). This leaves the fingers long

enough so you can sand them flush with the box later.

Step 8.

With your calipers, check the depth of the fingers in your scrap stock.

Adjust the height of your blade until the depth reads .016" more than the

width of your fingers (.266" in our example). This leaves the fingers long

enough so you can sand them flush with the box later.

Notice from the Treasurer:

DUES are due.

$10 for singles

$15 for families

NAME TAGS

The subject of name tags came up at the last meeting. Our name tags

were made by K&S TROPHIES , 510 Country Club Drive , Tullahoma.

They were about $5.00 including tax the last time we checked. When in Tullahoma

you can go by and have one made. The tags are 1" x 3" with white letters

on a blue background. Just tell the folks that you want a Tennessee Valley

Woodworkers name tag. If you are never in Tullahoma, Henry Davis will be

happy to take care of it for you, see him at the February meeting or give

him a call at 393 - 3191.

Mini Lathe Give Away.

To show our appreciation to our loyal and faithful members your Executive

Committee has again this year decided to give a prize to one lucky member.

Several prizes were suggested and the membership voted on the prize

we should give away. The overwhelming choice was a Mini Lathe. We have

purchased a Jet 14 inch Mini Lathe and it will be given away at our Christmas

gathering this December. The Lathe will be on display at our February meeting.

To be eligible to win the lathe just sign the drawing register at each

regular club meeting that you attend between now and December. That means

that if you attended the January meeting and attend every meeting from

now through November your name will be in the drawing 11 times.

The following rules will apply:

-

You may sign your name only, you may not sign your buddies or spouses name

because they just couldn’t make it to the meeting.

-

Each member of a family membership will be eligible; we consider the names

that appear on the membership list as family members.

-

You do not have to be present at the drawing to win.

-

Drawing will be open to members in good standing- etc, members who have

paid their 2002 dues.

-

The Executive Committee or their appointee reserves the right to remove

the name of any non-member whose name appears on the drawing register.

FOR SALE

I HAVE BOUGHT A NEW LARGER LATHE, AND AM SELLING THE FOLLOWING.

SEARS CRAFTSMAN LATHE.

12"SWING, 36" LONG

3450 RPM MAX,

WITH THE FOLLOWING:

MOUNTED ON WOOD TABLE WITH TOOL DRAWER.

BASIC SET OF CRAFTSMAN LATHE TOOLS

6" AND 12" TOOL RESTS.

4" FACE PLATE

ORIGINAL AND NEW 4 POINT SPUR CENTER DRIVES.

SCREW CENTER DRIVE.

DEAD AND LIVE TAIL STOCKS

10MM CHUCK

THIS IS THE SAME LATHE MADE BY RIDGID THAT IS CURRENTLY BEING SOLD AT

HOME DEPOT FOR $295. BASIC TOOLS AND ADDED ACCESSORIES COST APPROX.

$100-$120. PLUS THE TABLE. ASKING $175. WILL CONSIDER OFFERS.

I CAN BE REACHED AT MY OFFICE PHONE 931-962-1303 FROM 8:00AM TO 4:30

PM

THANKS,

KEN GOULD

Feburary program

This months program will be about routers. Tom Gillard and Henry Davis

will be talking about some router techniques that they have used. They

will also show several different type routers, router accessories and fixture

for the router. You need not bring your safety glasses or ear protection

as they don’t plan to make any live cuts.

Next Month

Of the 720,000 inuries per year associated with woodworking, 42 percent

happen at the tablesaw. Yet common sense, proven practices and tried techniques

will keep you from harm's way.

-------------------------------------------------------------------------------------------------------------

***************************************

"Briggs Paint on Atlantic street in Tullahoma will be carrying natural

color Deft Oil in gallon ($22.50) and Quart ($7.99) sizes as a test marketing

project. They should have it on the shelf before the end of January.

They will continue to carry it, if there is a demonstrated demand,

and maybe expand to carry the colors as well. See Jeff at the store

for questions or comments."

********************************

WEB

SITES of INTEREST

Scott

Phillips Video Help sessions

Arrowmont

School of Arts and Craft

WOOD

ONLINE newsletter

Falls Mill

Appalachain

Center for the Arts

Forest

Products Lab. 1999 Wood Handbook

Find

A Tree - Hangman Style! Tree identification

game...

Woodworker's

Journal

WOOD

Online TVWW page

Kevin's Woodturnings

The Oldham Company

The Woodworker's Choice

Russell Brown's Web Page

Saw Blade Sharpening Services: Branching Out is now offering their

services as a drop off spot to have your saw blades sharpened. The

blades will be picked up (Tuesdays), sharpened, and dropped back off at

Branching Out. The Leitz Tooling Systems out of Collierville, TN

will do the sharpening. Call (393-0525) or stop by for details.

10 % OFF Fine Woodworking

Books from Taunton Press

…We’re open Monday thru Saturday

Webmaster:

Tom Gillard Jr.

Vol. 17/ Issue2

February 2002

Editor: Tom Gillard Jr.

Vol. 17/ Issue2

February 2002

Editor: Tom Gillard Jr.

![]()

![]()

![]()

In the old days, youngsters

throughout the rural South went to the woods, not the grocery store, for

their chewing gum. There, they sought out a tree with unusual star-shaped

leaves and bark resembling alligator skin. From it they pried off, then

popped into their mouths, yellowish brown balls of a fragrant, resinous

substance with a licorice-like taste. Their treat was the sap of the native

sweet gum tree (Liquidambar styraciflua). Little did they know that this

natural confection, called liquidambar, had been in demand for centuries.

In the old days, youngsters

throughout the rural South went to the woods, not the grocery store, for

their chewing gum. There, they sought out a tree with unusual star-shaped

leaves and bark resembling alligator skin. From it they pried off, then

popped into their mouths, yellowish brown balls of a fragrant, resinous

substance with a licorice-like taste. Their treat was the sap of the native

sweet gum tree (Liquidambar styraciflua). Little did they know that this

natural confection, called liquidambar, had been in demand for centuries.

Step 8.

With your calipers, check the depth of the fingers in your scrap stock.

Adjust the height of your blade until the depth reads .016" more than the

width of your fingers (.266" in our example). This leaves the fingers long

enough so you can sand them flush with the box later.

Step 8.

With your calipers, check the depth of the fingers in your scrap stock.

Adjust the height of your blade until the depth reads .016" more than the

width of your fingers (.266" in our example). This leaves the fingers long

enough so you can sand them flush with the box later.