SPLINTERS |

|

Tennessee Valley Woodworkers Vol. 15/ Issue 2 February 2000 Editor: Tom Gillard |

||

|

|

Meeting Notice: The next meeting of the TN Valley Woodworkers Will be held, February 15, at 7:00 p.m. in the Duck River Electric Building, Decherd, TN All interested woodworkers are invited! |

|

It is very sad to report that since the last meeting Jack Townsend has passed away. Jack had been a long time woodworker, club member, friend and good fisherman. We will all miss him and his clock making. There will be a memorial book placed in the Franklin County Library. The title will be announced later.

TVWW MINUTES JANUARY 18, 2000

The meeting was called to order by President Tom Cowan at 7:00 PM. Tom reported that Jack Townsend was in the hospital suffering from viral pneumonia.

Welcome guest was Dave White.

Announcements -

“CREATIONS IN WOOD" Chairman Jim Roy reported that he and his committee need the participation of the entire club, both for items to display and manpower to set up and oversee the displays at the three locations.

TREASURERS REPORT = Treasurer Henry Davis gave an accounting of the major income and expenditures for the year 1999. There was a balance of $988 at the end of the year.

Old Business - none

New Business - Larry Halbeck has wood available from an old barn in Beech Grove. This wood is free for the taking. Contact Larry if you are interested. Bob Reese stated that the February program would be on circular saw technology. Gary Runyon has a friend with many tools for sale. A list was available at the meeting. Tom solicited input from all members to aid in plans for the coming year. He mentioned workshops, seminars, Christmas party, picnic, field trip, ombudsman and monthly meetings. This list can be expanded if any member desires.

SHOW AND TELL

MANUEL BROWN - is still working toward mastering his lathe technique. He showed a laminated bowl and two other small bowls.

GARY RUNYON - brought a knife that he had forged and a chip carving knife. Gary and his wife also brought a handloom with a work in progress.

BOB REESE - had a piece of unidentified wood. The consensus seemed to be that it was sycamore. WINFIELD BENNET - proudly showed two examples of his artistic abilities with carved dolphins. BEN WHITEAKER - a cherry rocking horse made for his grandson.

ROSS ROEPKE - a cherry and walnut desk made for one of his grandchildren.

HENRY DAVIS - a book detailing the history of the club, from inception to present day. It includes a copy of all of the newsletters and pictures of various events, JIM ROY- a walnut hand mirror. One of a number that he made for Christmas gifts. Also a jig that he has used since his early days of woodworking. MAURICE RYAN - Two circular saw blade holders made from plywood and milk bottle caps.

After a short break various members showed jigs and gadgets used for a single purpose or adapted for multiple uses.

There were a total of 49 members and guests in attendance. The meeting adjourned at 8:40PM.

Respectfully submitted, John Green for Secretary John Mayberry

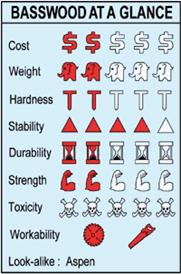

Basswood

Carvers make a beeline for this tree

Among the most important of America’s nectar-producing trees, the basswood makes itself at home along city streets as well as in the forest. In cityscapes, nurserymen call the hardy, decorative tree American linden. But in the woods, it’s basswood, beetree, lime, or whitewood. Regardless of its name, basswood has proven its value.

Indians of New York State's Iroquois nation carved ceremonial masks from the sapwood of living basswood trees, then split the green-wood masks from the trunk. The gummy inner bark provided bandages. And from its dried fibers they wove rope.

Beekeepers even today appreciate the quality of basswood-derived honey. In summer, the tree’s fragrant flower clusters provide a strong-flavored nectar. Basswood stock also becomes the very boxes in which the honeycombs are stored and shipped.

Wood identification

The forest-products industry lumps the four native North American basswood species together in the marketplace, for there are few differences between

them, except where they grow. Tilia americana, of the northern Great Lakes states, provides most of the basswood harvested.

In a setting of mixed hardwoods in the well-drained ground of a stream valley, basswood can grow to 90' tall with a straight trunk 3' in diameter. But because basswood sprouts from the stump, it’s often seen as a clump of three or four smaller trunks.

Young basswood trees feature light gray, smooth bark, while that of older trees becomes darker and deeply ridged. In late winter, small reddish-brown buds appear on branch twigs. Their nutlike flavor signals that you’ve found a basswood tree.

When leaves form, they have a distinctive heart shape with lightly serrated edges. The leaves also display an unusual trait: The undersides, not the tops, are shiny. Clusters of sweet-smelling white or cream-colored flowers follow the leaves.

Weighing about 26 pounds per cubic foot air-dried, the wood has a tan color, and in some cases may be nearly white. You’ll find the grain of this soft hardwood straight, close, and normally featureless. Occasional basswood stock may display some dark stain, which doesn’t affect the wood’s performance but may mar a project. Dry basswood is stable.

Uses in

woodworking

Carvers prefer basswood because it holds detail well, doesn’t split, has straight-grain, and carves easily. They usually prefer air-dried, slow-grown northern stock.

Basswood also can become drawer stock, hidden furniture parts, and painted items.

In industry, it plays a role as boxes and food containers. As veneer, it can underlie fine cabinet woods in plywood. This light, versatile wood also works for picture frames, toys, and millwork such as window sashes. It even makes fine turning wood.

AvailabiIity

AvailabiIity

Many large hardwood retailers outside its natural range carry basswood in board form. Specialty suppliers offer basswood carving blocks and blanks.

Expect to pay around $2 per board foot for select and better 4/4 stock, and about $3 and more per board foot for thicker boards. Veneer isn’t available at retail.

Both northern and southern varieties of basswood show little contrast between early wood and late wood, although northern basswood provides tighter-grained, finer-textured stock. Carvers also will want to avoid basswood with mineral stains, unless the project will be painted.

If you're a carver who likes to gather stock yourself—and live where basswood grows—try this method to dry your wood. Harley Refsal, WOOD® magazine's carving consultant, dries his northern- Iowa basswood this way: He cuts 18" lengths from a log or large branch, then halves and quarters them with an ax. Next, he removes the pith (inner core of the heartwood) and wraps each quarter completely with two layers of newspaper. Harley fastens the wrapped stock between the floor joists in his basement furnace room and leaves them to air dry for six to eight weeks. In the summertime, he dries the wood overhead in the garage.

Not a carver? You still may want to try this easily worked wood. Here's some guidance:

Machining methods

Basswood's low-hardness rating makes it ideal for hand tools. Power planing basswood poses no problems. You'll find jointing effortless, too.

Because the wood is dense, ripping requires a rip-set blade with 24 teeth or less to avoid burning. In crosscutting, it won't tear out or chip. Use sharp bits and don't rush the router when shaping basswood, as its tight grain and density does tend to burn (although burns easily sand off). Unlike some other lightweight, straight-grained woods (such as redwood), basswood fastens well with nails or screws. And it's not necessary to pre-drill. Sanding basswood proves to be a soothing, smoothing task. But when it comes to staining, blotching can result. If uneven staining appears on a test piece, apply wood conditioner before staining. Remember, though, even wood conditioner won't subdue discolored streaks in the wood.

Carving comments

It would be hard to find a wood more perfect for carving. A sharp knife or gouge slides through it as if cutting butter. And the finish of a clean cut looks lustrous. Because basswood takes fine detail, it's great for relief, figure, and chip carving. Basswood requires control or your carving tool may go further along a stroke than planned. Strengthen details subject to breakage with a thinned coat of woodworker's glue (it won’t take stain) worked into the wood.

Turning tips

Woodturners will find basswood superb for food containers, since it imparts no odor or taste.

SHOP-TESTED TECHNIQUES THAT ALWAYS WORK

For stability in use, always work wood with a maximum moisture content of 8 percent. Feed straight-grained wood into planer knives at a 90° angle. To avoid tearing, feed figured wood or twisted grain at a slight angle (about 15°), and take shallow cuts of about 1/32". For clean cuts, rip with a rip-profile blade that has 24-32 teeth. Smooth crosscutting requires at least a 40-tooth blade.

Avoid using twist drills. They tend to wander and cause breakout. Use brad-point bits and a backing board under the workpiece to reduce tearout. Drill pilot holes for screws. Rout with sharp, preferably carbide-tipped, bits and take shallow passes to avoid burning. Carving softwoods, and a soft hardwood like basswood, means fairly steep gouge bevels—greater than 20°.

CREATIONS IN WOOD EXHIBIT

Objectives of the Event

(a) To promote fellowship and fun within the club

through teamwork and maximum participation.

(b) To acquaint the public with TVWW’s existence, talent, and membership

opportunities.

(c) To challenge club members ,new and old, to exercise their woodworking

skills and build quality products for display.

Ground Rules for Display Items

(a) Must be built by submitting member.

(b) Must be made primarily from wood.

(c) Must not have been in previous exhibit. (Magic in Wood)

(d) Must not be built from a kit.

(e) More than one item is acceptable.

(f) Recent construction encouraged but not required.

Dates and Locations

(a) Week of April 7.........Winchester Library

(b) Week of April 24............Tullahoma Library

(c) Week of May 1......Foothills Crafts (Manchester)

It is hoped that all members will participate. If you plan to enter an item(s), please use the sign-up sheets available at each meeting. If you would like to help with transporting items to and from the exhibit sites or would like to help with meeting the public please let us know this also on the sign-up sheet.

Jim Roy, Committee Chairman